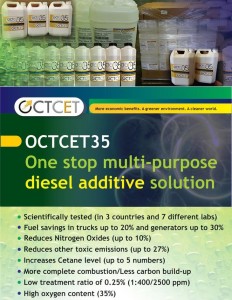

OCTCET DIESEL FUEL ADDITIVE

THE PRODUCT

OCTCET 35 treated fuel widens the limits of the combustibility of fuels and leaves substantially less unburned fuel to escape through the exhaust tailpipe due to its high oxygen content and its ability to reduce the ignition delay during the combustion process.

OCTCET 35 is an alternative for 2-ethylhexyl nitrate (2-EHN), by increasing the cetane number with 5-20 numbers with the addition of 0.25% OCTCET 35. An increase in cetane number can significantly reduce hydrocarbon and carbon monoxide emissions in all diesel fuels.

OCTCET 35 is unique in its chemistry as it is not based on MTBE, DME, DMM, TAME, FAME, DIPE, methanols, ethanols, acetone, carbonates, glycol ethers, etc. OCTCET 35 is a proprietary blend of organic intermediates.

OCTCET 35, after tests conducted by Millbrook Testing Facility in Bedford, UK in July 2011 with a 1% blend, showed the following statistical improvements compared to baseline:

- Total Hydrocarbons (THC) reduced by 37.18%.

- Carbon Monoxide (CO) reduced by 37.11%.

- 1.2% reduction in Carbon Dioxide (CO2).

Further tests, conducted by a reputable and EPA Accredited Testing Facility, where a blend of 0.25% of OCTCET will be inserted into diesoline in order to even further reduce Nitrogen Oxides to a -6% – -8% reduction is to be done soon.

THE BENEFITS

ECONOMIC BENEFITS

- Improved fuel economy.

- Excellent bactericide.

- Easy dosing at refinery level.

ENVIRONMENTAL BENEFITS

- Substantial reduction in emissions.

- No nitrogen content.

- Halogen-free.

- Improved conductivity (less flammable).

MECHANICAL BENEFITS

- Significant cetane improvement properties.

- More complete combustion.

- Less carbon build-up on injector nozzles.

- Prolonged engine life.

- No side effects on fuel line components.

- More power.

- Easier start in cold weather.

- Ignition energy < 0,1 mJ.

OTHER BENEFITS

- Low treatment ratio = 1:400/0.25%.

- High oxygen content >35%.

- Excellent surface reduction properties.

- Emulsifier properties.

- Only 10% aromatic footprint (fuel maintains 31% aromatic content).

- Thermally and oxidative stable.

OCTCET 35 reduces toxic carbon emissions and plays an important role in lowering ground level ozone as a greenhouse gas by the reduction of hydrocarbons as a precursor to photochemical smog which is a contributor to climate change and global warming.

The Clean Diesel Verification Process evaluates the emission reduction performance and durability of retrofit and clean diesel technologies, and provides users with confidence that the technology will perform as expected.

Date: November 2012-Before being placed on the Verified Technology List, the technology must go through a thorough technical review and tightly controlled testing to quantify statistically significant levels of emission reductions. For the State of Texas the TCEQ estimates that the entire process could take up to three months to complete depending upon the provision of the TxLED regulations under which the applicant is seeking approval.

Having concluded the most stringent scientific tests at the OEM accredited laboratory namely Millbrook Proving Grounds in the UK and further tests are in process. OCTCET Inc. has no doubt that approval will be a formality.